Lintlha tse qaqileng

Letoto la SILIKE Si-TPV 2150 ke elastomer e matla e thehiloeng ho silicone e nang le vulcanizate, e ntlafalitsoeng ho sebelisoa theknoloji e tsoetseng pele ea ho lumellana. Ts'ebetso ena e hasanya rabara ea silicone ho SEBS e le likaroloana tse tšesaane, ho tloha ho 1 ho isa ho 3 microns tlas'a microscope. Lisebelisoa tsena tse ikhethang li kopanya matla, ho tiea le ho hanyetsa ho khohlela ha li-elastomer tsa thermoplastic le thepa e lakatsehang ea silicone, joalo ka bonolo, ho ikutloa joaloka silika, le ho hanyetsa khanya ea UV le lik'hemik'hale. Ho feta moo, lisebelisoa tsa Si-TPV li ka sebelisoa hape 'me li ka sebelisoa hape lits'ebetsong tsa tlhahiso ea setso.

Si-TPV e ka sebelisoa ka kotloloho e le thepa e tala, e etselitsoeng ka ho khetheha lits'ebetso tsa ho bopa ka mokhoa o bonolo ka ho ama ka holim'a lisebelisoa tsa elektroniki tse aparoang, mabokoseng a sireletsang bakeng sa lisebelisoa tsa elektroniki, likarolo tsa likoloi, li-TPE tsa maemo a holimo, le indasteri ea terata ea TPE.

Ntle le tšebeliso ea eona e tobileng, Si-TPV e ka boela ea sebetsa e le sesebelisoa sa ho fetola polymer le ho eketsa ts'ebetso bakeng sa li-elastomer tsa thermoplastic kapa li-polymer tse ling. E eketsa ho tenyetseha, e ntlafatsa ts'ebetso, 'me e matlafatsa litšobotsi tsa bokaholimo. Ha e kopantsoe le TPE kapa TPU, Si-TPV e fana ka boreleli ba bokaholimo bo tšoarellang nako e telele le maikutlo a monate a ho ama, ha ka nako e ts'oanang e ntlafatsa ho hanyetsa ho ngoapa le ho khohlela. E fokotsa ho thatafala ntle le ho ama litšobotsi tsa mechini hampe 'me e fana ka khanyetso e betere ea botsofali, bosehla le matheba. E ka boela ea etsa qetello e lakatsehang ea matte holim'a bokaholimo.

Ho fapana le di-additives tse tlwaelehileng tsa silicone, Si-TPV e fanwa ka sebopeho sa pellet mme e sebetswa jwalo ka thermoplastic. E hasana hantle le ka ho lekana ho pholletsa le matrix ya polymer, mme copolymer e tlamahana ka mmele le matrix. Sena se fedisa matshwenyeho a ho falla kapa mathata a "ho thunya", e leng se etsang hore Si-TPV e be tharollo e sebetsang le e ntjha bakeng sa ho fihlella dibaka tse bonolo tse kang siliki ho di-elastomer tsa thermoplastic kapa di-polymer tse ding. mme ha e hloke mehato e eketsehileng ya ho e lokisa kapa ho e roala.

Melemo ea Bohlokoa

- Ka TPE

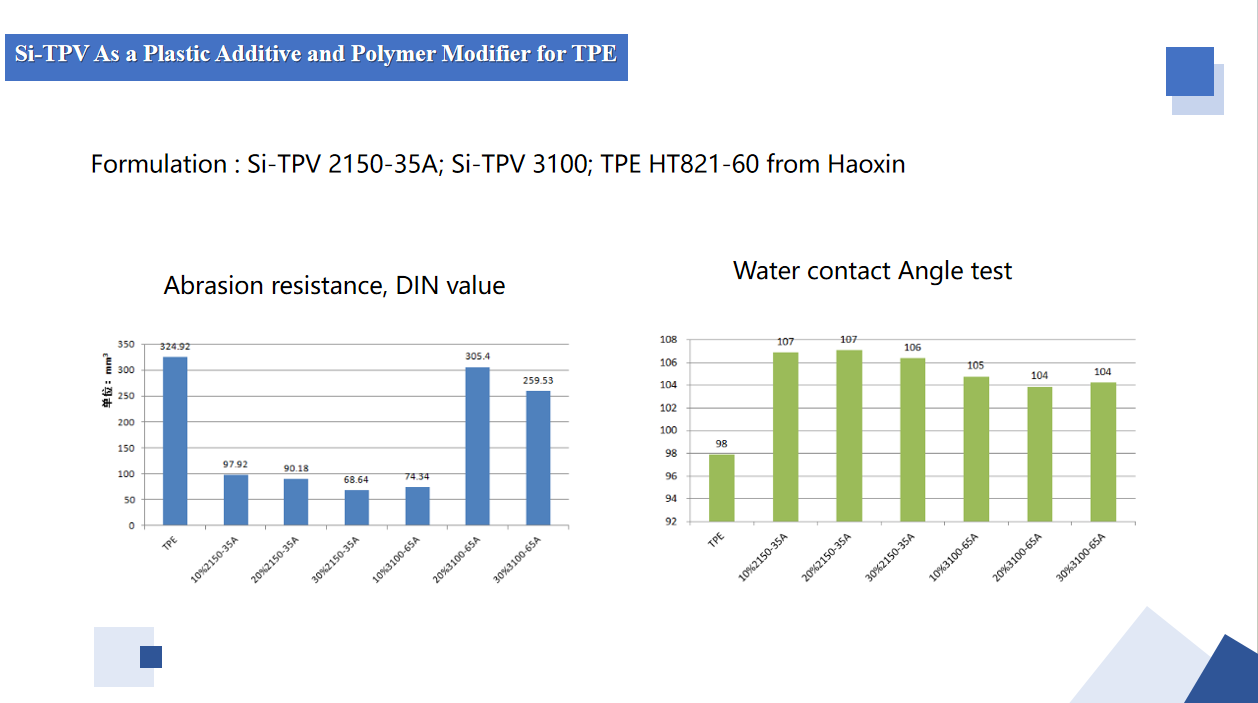

- 1. Khanyetso ea ho khohlela

- 2. Ho hanyetsa matheba ka sekhutlo se senyenyane sa ho kopana le metsi

- 3. Fokotsa ho thatafala

- 4. Ha ho na tšusumetso e kaalo hodima thepa ya mechini ka letoto la rona la Si-TPV 2150

- 5. Li-haptic tse ntle haholo, ho omella ha silika, ha ho thunya kamora tšebeliso ea nako e telele

Ho tšoarella Botsitso

- Theknoloji e tsoetseng pele e se nang ditharollo, e se nang polasetiki, e se nang oli e nolofatsang, ebile e se na monko.

- Tšireletso ea tikoloho le ho sebelisoa hape.

- E fumaneha ka mekhoa e lumellanang le melaoana.

Lithuto tsa Nyeoe tsa ho eketsa polasetiki ea Si-TPV le modifier ea polymer

Letoto la Si-TPV 2150 le na le litšobotsi tsa ho ama letlalo ka bonolo nako e telele, ho hanyetsa matheba hantle, ho se be le polasetiki le senolofatsi se ekelitsoeng, le ho se be le pula kamora tšebeliso ea nako e telele, e sebetsang e le sesebelisoa sa polasetiki le polymer modifier, haholo-holo se sebelisoang hantle bakeng sa ho lokisa li-elastomer tsa thermoplastic tse monate tse ikutloang li le silky.

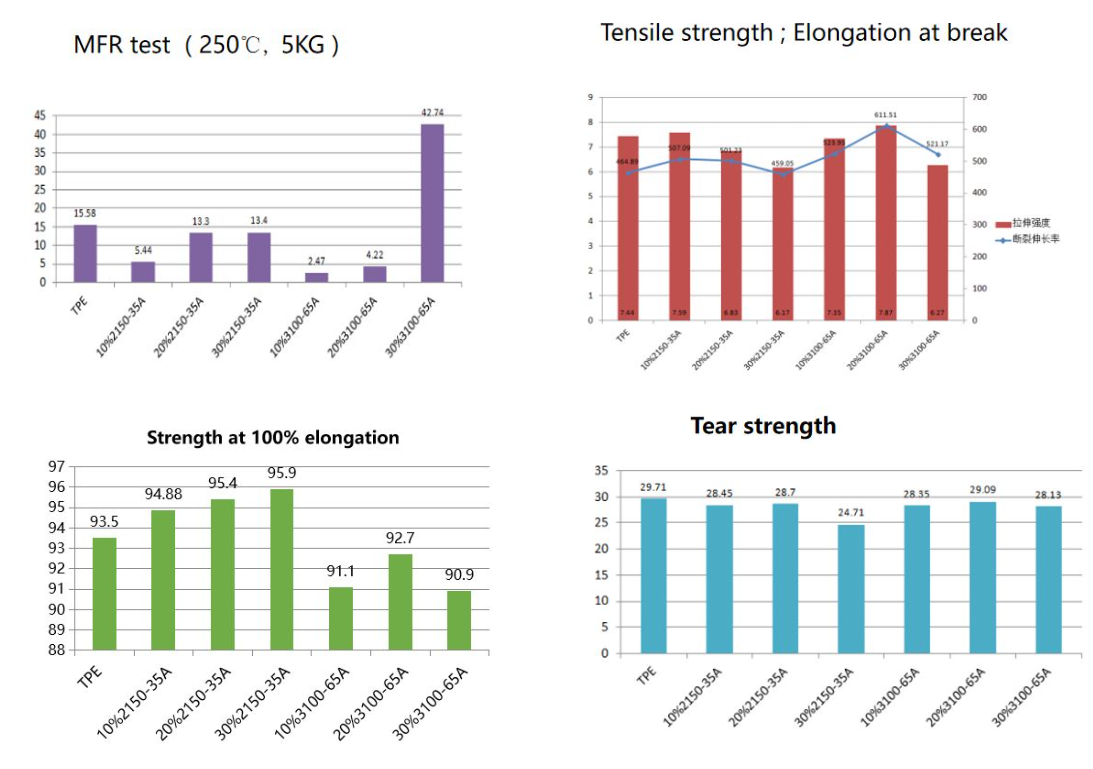

Ho Bapisa Litlamorao tsa Si-TPV Plastic Additive le Polymer Modifier ho Tshebetso ea TPE

Kopo

Si-TPV e sebetsa e le sesebelisoa se secha sa ho fetola maikutlo le ho eketsa ts'ebetso bakeng sa li-elastomer tsa thermoplastic le li-polymer tse ling. E ka kopanngoa le li-elastomer tse fapaneng le boenjiniere kapa polasetiki e akaretsang, joalo ka TPE, TPU, SEBS, PP, PE, COPE, EVA, ABS le PVC. Litharollo tsena li thusa ho ntlafatsa katleho ea ts'ebetso le ho ntlafatsa ts'ebetso ea ho hanyetsa ho ngoapa le ho khoptjoa ha likarolo tse felileng.

Molemo o ka sehloohong oa lihlahisoa tse entsoeng ka metsoako ea TPE le Si-TPV ke ho etsoa ha bokaholimo bo bonolo bo sa thekeseleng—hantle-ntle phihlelo eo basebelisi ba qetello ba e lebellang linthong tseo ba li amang kapa ba li aparang khafetsa. Tšobotsi ena e ikhethang e atolosa mefuta e mengata ea lits'ebetso tse ka bang teng bakeng sa thepa ea elastomer ea TPE ho pholletsa le liindasteri tse ngata. Ho feta moo, ho kenyelletsa Si-TPV e le modifier ho ntlafatsa ho tenyetseha, ho tenyetseha le ho tšoarella ha thepa ea elastomer, ha ka nako e ts'oanang ho etsa hore ts'ebetso ea tlhahiso e be e theko e tlaase haholoanyane.

Litharollo:

Na o Loanela ho Ntlafatsa Tshebetso ya TPE? Di-additives tsa polasetiki tsa Si-TPV le di-polymer modifiers di fana ka karabo

Selelekela ho TPE

Li-elastomer tsa Thermoplastic (TPEs) li arotsoe ka likarolo tsa lik'hemik'hale, ho kenyeletsoa Thermoplastic Olefins (TPE-O), Styrenic Compounds (TPE-S), Thermoplastic Vulcanizates (TPE-V), Polyurethanes (TPE-U), Copolyesters (COPE), le Copolyamides (COPA). Leha li-polyurethanes le li-copolyesters li ka 'na tsa etsoa ka mokhoa o feteletseng bakeng sa lits'ebetso tse ling, likhetho tse theko e tlaase tse kang TPE-S le TPE-V hangata li fana ka mokhoa o loketseng lits'ebetso.

Li-TPE tse tloaelehileng ke motsoako oa 'mele oa rabara le li-thermoplastic, empa li-TPE-V lia fapana ka ho ba le likaroloana tsa rabara tse hokahaneng ka karolo e itseng kapa ka botlalo, e leng se ntlafatsang ts'ebetso ea tsona. Li-TPE-V li na le li-sete tse tlase tsa khatello, khanyetso e ntle ea lik'hemik'hale le ho khohlela, le botsitso bo phahameng ba mocheso, e leng se etsang hore li be ntle bakeng sa ho nkela rabara sebaka ka har'a litiiso. Ka lehlakoreng le leng, li-TPE tse tloaelehileng li fana ka ho tenyetseha ho hoholo ha sebopeho, matla a ho tsikinyeha a phahameng, ho tenyetseha le ho ba le 'mala o motle, e leng se etsang hore li lokele lihlahisoa tse kang thepa ea bareki, lisebelisoa tsa elektroniki le lisebelisoa tsa bongaka. Li boetse li hokahana hantle le li-substrate tse thata joalo ka PC, ABS, HIPS, le Nylon, e leng molemo bakeng sa lits'ebetso tse bonolo.

Liphephetso ka TPE

Li-TPE li kopanya ho tenyetseha le matla a mechini le ho sebetsa habonolo, e leng se etsang hore li be le mekhoa e mengata haholo. Litšobotsi tsa tsona tsa ho tenyetseha, tse kang sete ea khatello le ho lelefala, li tsoa mohatong oa elastomer, ha matla a ho tenyetseha le ho taboha a itšetlehile ka karolo ea polasetiki.

Li-TPE li ka sebetsoa joalo ka li-thermoplastic tse tloaelehileng mochesong o phahameng, moo li kenang mohatong oa ho qhibiliha, e leng se lumellang tlhahiso e sebetsang hantle ho sebelisoa lisebelisoa tse tloaelehileng tsa ho sebetsana le polasetiki. Mokhahlelo oa tsona oa mocheso o sebetsang le oona oa hlokomeleha, ho tloha mochesong o tlase haholo—haufi le ntlha ea phetoho ea khalase ea mohato oa elastomer—ho ea mochesong o phahameng o haufi le ntlha ea ho qhibiliha ea mohato oa thermoplastic—ho eketsa ho tenyetseha ha tsona.

Leha ho le jwalo, ho sa tsotellehe melemo ena, diphephetso tse mmalwa di ntse di tswela pele ho ntlafatsa tshebetso ya di-TPE. Bothata bo bong bo boholo ke bothata ba ho leka-lekanya ho tenyetseha le matla a mechini. Ho ntlafatsa thepa e nngwe hangata ho tlisa tahlehelo ya e nngwe, e leng se etsang hore ho be thata hore bahlahisi ba hlahise diforomo tsa TPE tse bolokang botsitso bo tsitsitseng ba dikarolo tse lakatsehang. Ho feta moo, di-TPE di kotsing ya ho senngwa ke bokahodimo jwalo ka maqeba le matheba, e leng se ka amang ponahalo le tshebetso ya dihlahiswa tse entsweng ka thepa ena hampe.