Lintlha

SILIKE Si-TPV 2250 Series ke elastomer e matla ea thermoplastic e thehiloeng ho thermoplastic e etselitsoeng ho ntlafatsa thepa e phophomang ea EVA. Si-TPV 2250 Series e hlahisoa ho sebelisoa theknoloji e khethehileng e netefatsang hore rabara ea silicone e hasanngoa ka ho lekana ho EVA e le likaroloana tsa 1-3 tsa micron. Mofetoleli ona o ikhethileng oa thepa e phophomang ea EVA e kopanya matla, ho tiea, le ho haneloa ha li-elastomer tsa thermoplastic le thepa e lakatsehang ea silicone, ho kenyelletsa bonolo, maikutlo a silika, ho hanyetsa UV, le khanyetso ea lik'hemik'hale. E ka sebelisoa hape le ho sebelisoa hape mekhoeng ea khale ea tlhahiso.

Lisebelisoa tsa Si-TPV 2250 Series Eco-Friendly Soft Touch Material li lumellana haholo le ethylene-vinyl acetate (EVA) 'me li sebetsa e le sesebelisoa sa silicone se ntlafatsang bakeng sa EVA Foaming, Litharollo tsa ho ntlafatsa lisebelisoa tsa foam tsa EVA lits'ebetsong tse kang sole ea lieta, lihlahisoa tsa bohloeki, lihlahisoa tsa boikhathollo tsa lipapali, mete ea fatše, mete ea yoga le tse ling.

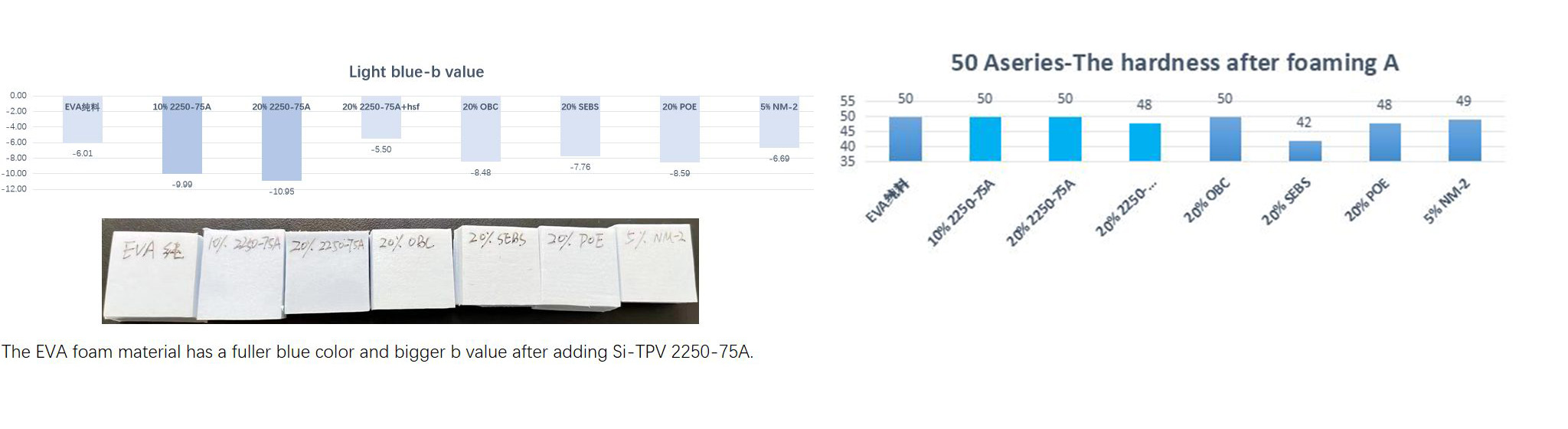

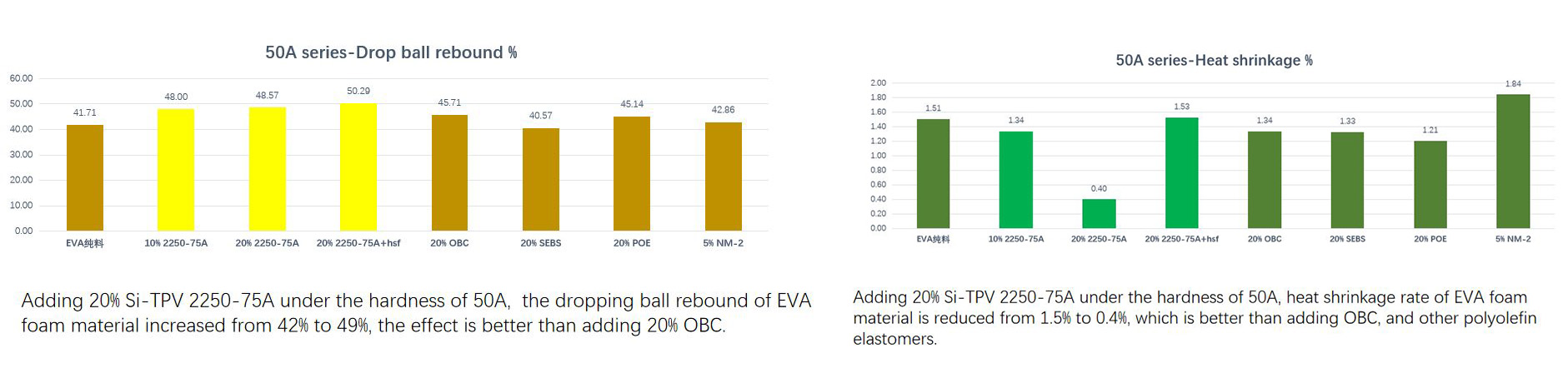

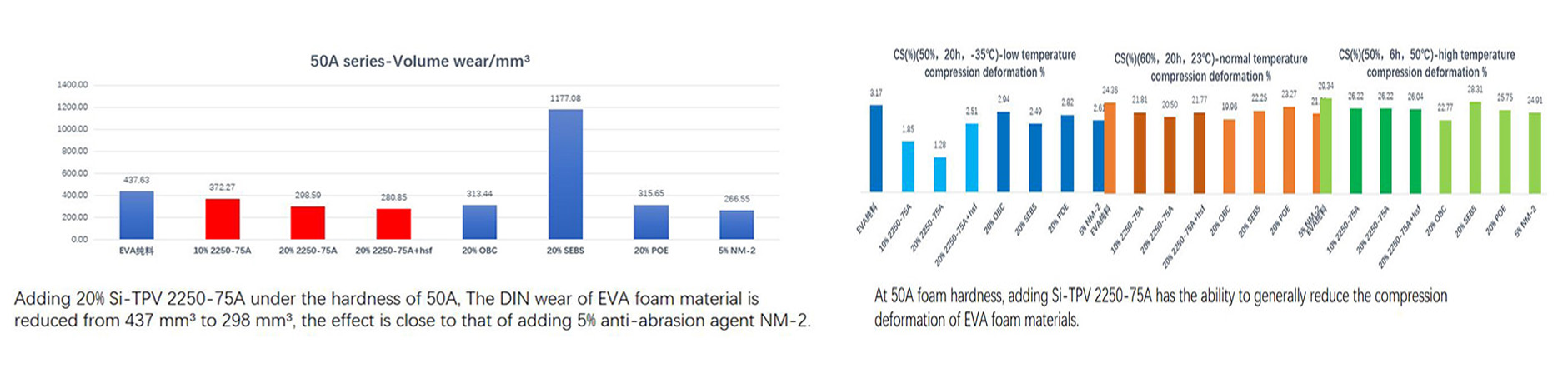

Ha ho bapisoa le OBC le POE, Highlight e fokotsa sekhahla sa khatello le mocheso oa mocheso oa thepa ea foam ea EVA, e ntlafatsa elasticity le bonolo ba EVA foaming, e ntlafatsa ho thibela ho thella le ho thibela ho senya, 'me moaparo oa DIN o fokotsehile ho tloha ho 580 mm3 ho ea ho 179 mm3 mme o ntlafatsa ho phalla ha mebala ea thepa ea foam ea EVA.

Tse ipakileng li sebetsa ka katleho Flexible Soft Eva Foam Material Solutions.

Melemo ea Bohlokoa

Durability Ho tšoarella

- Theknoloji e tsoetseng pele e se nang solvent, ntle le polasetiki, ha e na oli e nolofatsang, ebile ha e na monko.

- Tšireletso ea tikoloho le ho sebelisoa hape.

- E fumaneha ka mekhoa e lumellanang le melao.

Si-TPV Modifier Bakeng sa lithuto tsa EVA Foaming Case

Si-TPV 2250 Series e na le ts'ebetso e bonolo ea nako e telele ea letlalo, e hanyetsanang hantle le matheba, 'me ha e hloke ho eketsoa ha li-plasticizers kapa softeners. E boetse e thibela pula ka mor'a tšebeliso e telele. Joalo ka mokhoa o lumellanang haholo le o nchafalitsoeng oa foam o bonolo oa Eva, o loketse ka ho khetheha bakeng sa ho lokisoa ha thepa e phophomang ea EVA e bobebe haholo, e otlolohileng haholo, e sebetsang hantle ka tikolohong.

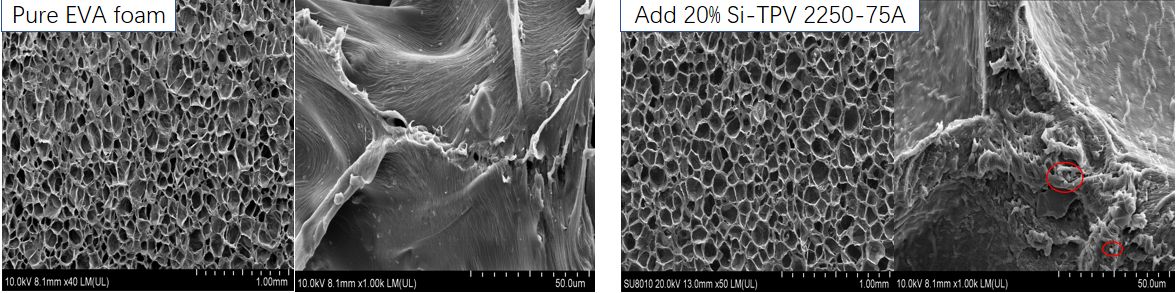

Ka mor'a ho eketsa Si-TPV 2250-75A, bubble cell density ea EVA foam e fokotseha hanyenyane, lerako le teteaneng, 'me Si-TPV e qhalakanngoa leboteng la bubble, lerako la bubble le fetoha le thata.

Papiso ea Si-TPV2250-75A le litlamorao tsa tlatsetso ea polyolefin elastomer ho foam ea EVA

Kopo

Novel e tala tikoloho e lumellanang le Si-TPV modifier e matlafatsang thepa e phophomang ea EVA e fetotseng bophelo ba letsatsi le letsatsi le liindasteri tsa lihlahisoa tsa mesebetsi ea khoebo. joalo ka lieta, lihlahisoa tsa bohloeki, mesamo ea bate, lihlahisoa tsa boikhathollo tsa lipapali, limmete tsa fatše/yoga, lintho tsa ho bapala, liphutheloana, lisebelisoa tsa bongaka, lisebelisoa tsa ts'ireletso, lihlahisoa tsa metsi tse sa thelleng, le liphanele tsa photovoltaic...

Haeba u tsepamisitse maikutlo litharollong tsa ho phophoma ka matla haholo, ha re na bonnete ba hore na ke molemong oa hau, empa sesebelisoa sena sa Si-TPV se fetola theknoloji ea khemikhale e phophomang. Bakeng sa bahlahisi ba foaming ba EVA e ka ba mokhoa o mong oa ho etsa lihlahisoa tse bobebe le tse tenyetsehang tse nang le litekanyo tse nepahetseng.

Litharollo:

Ho ntlafatsa EVA Foams: Ho Rarolla Liphephetso tsa EVA Foam ka Si-TPV Modifiers

1. Kenyelletso ea EVA Foam Materials

Lisebelisoa tsa foam tsa EVA ke mofuta oa foam ea sele e koetsoeng e hlahisoang ka motsoako oa ethylene le vinyl acetate copolymers, e nang le polyethylene le li-agent tse fapa-fapaneng tse foaming le li-catalyst tse hlahisoang nakong ea tlhahiso. E tsebahala ka cushion ea eona e phahameng, ho monya ho ts'oha, le ho hanyetsa metsi, foam ea EVA e na le sebopeho se bobebe empa se tšoarella se fanang ka ho kenya letsoho hantle haholo. Mehaho ea eona e tsotehang e etsa hore EVA foam e be thepa e fapaneng, e sebelisoang haholo lihlahisoa tsa letsatsi le letsatsi le lisebelisoa tse khethehileng ho pholletsa le indasteri e fapaneng, joalo ka lieta, meseme e bonolo ea foam, li-yoga blocks, li-kickboards tsa ho sesa, fatše ka tlas'a lefatše, joalo-joalo.

2. Mefokolo ea Liforomo tsa Tloaelo tsa EVA ke Efe?

Batho ba bangata ba nahana hore thepa ea foam ea EVA ke motsoako o phethahetseng oa khetla e thata le khetla e bonolo, Leha ho le joalo, tšebeliso ea lisebelisoa tsa EVA tse foamed e lekanyelitsoe ho isa bohōleng bo itseng ka lebaka la ho hanyetsa botsofali bo fokolang, ho hanyetsa ha flexure, elasticity, le abrasion resistance. Ho phahama ha ETPU lilemong tsa morao tjena le papiso ea lisampole le tsona li etsa hore lieta tsa EVA tse foamed li tlameha ho ba le boima bo tlase, ho phahama ho hoholo, deformation e tlase ea compression, le lisebelisoa tse ling tse ncha.

Ho feta moo, Mathata a Tikoloho le Bophelo bo Botle ba EVA Foam Production.

Lihlahisoa tse entsoeng ka makokoane tsa EVA tse fanoeng 'marakeng hajoale li lokisitsoe ka mokhoa oa ho foka ka lik'hemik'hale 'me li sebelisoa haholo-holo bakeng sa lihlahisoa tse kang lisebelisoa tsa lieta, limmete tsa fatše, le tse ling tse joalo tse amanang le' mele ea batho ka ho toba. Leha ho le joalo, thepa e phophomang ea EVA e lokiselitsoeng ke mokhoa le ts'ebetso e na le ts'ireletso ea tikoloho le mathata a bophelo bo botle, 'me haholo-holo, lintho tse kotsi (haholo-holo formamide) li lula li arohane le bokahare ba sehlahisoa ka nako e telele.