Lintlha tse qaqileng

Thepa ke mokhoa oa thepa oa ho phethahatsa sehlahisoa, mojari oa theknoloji le mosebetsi, le mokena-lipakeng oa puisano pakeng tsa batho le lihlahisoa. Bakeng sa lihlahisoa tsa ho silila, boqapi ba thepa ke haholo-holo tšebeliso ea thepa e ncha, ke hore, thepa e ncha ka nako e nepahetseng, e loketseng lisebelisoa tsa ho silila nts'etsopele ea sehlahisoa se secha. Tšebeliso ea thepa ea saense le theknoloji liphetho tse ncha tsa lihlahisoa tsa setso li tla hlahisa setšoantšo se secha sa ponahalo, li fe batho maikutlo a phutholohileng a pono le maikutlo a amang, ho fihlela ts'ebetso e betere ea tšebeletso bakeng sa batho.

Melemo ea Bohlokoa

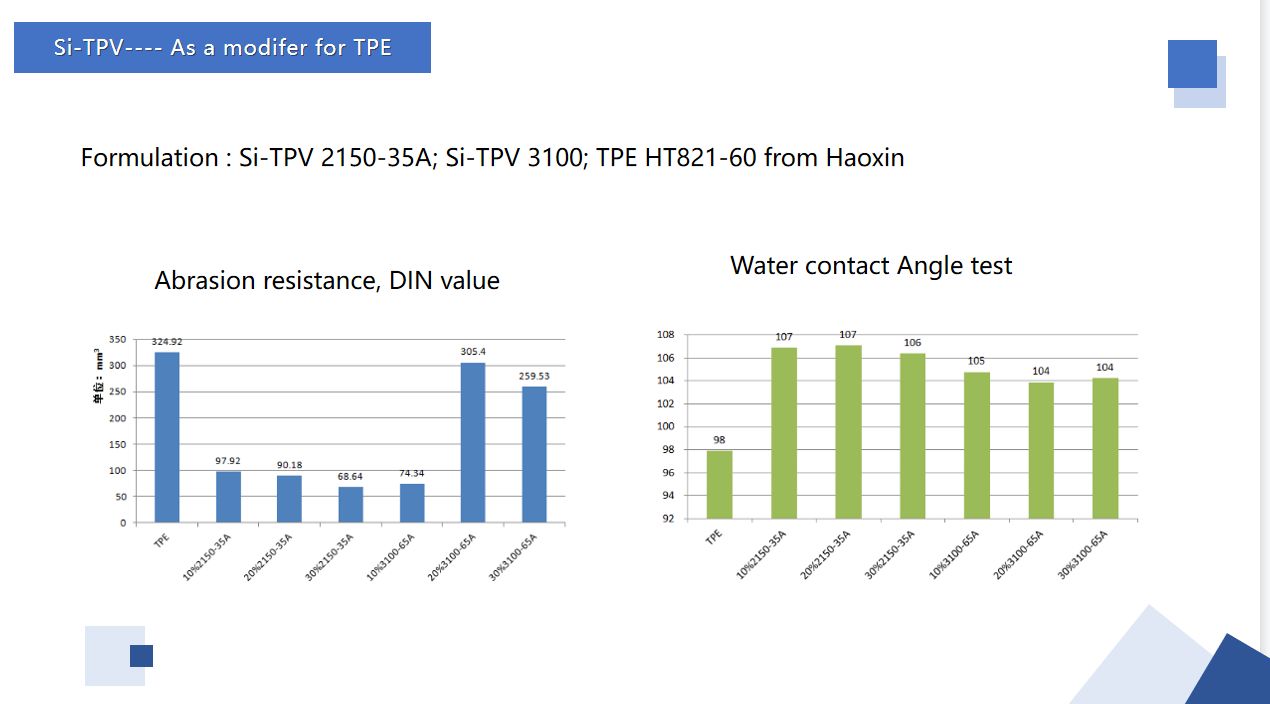

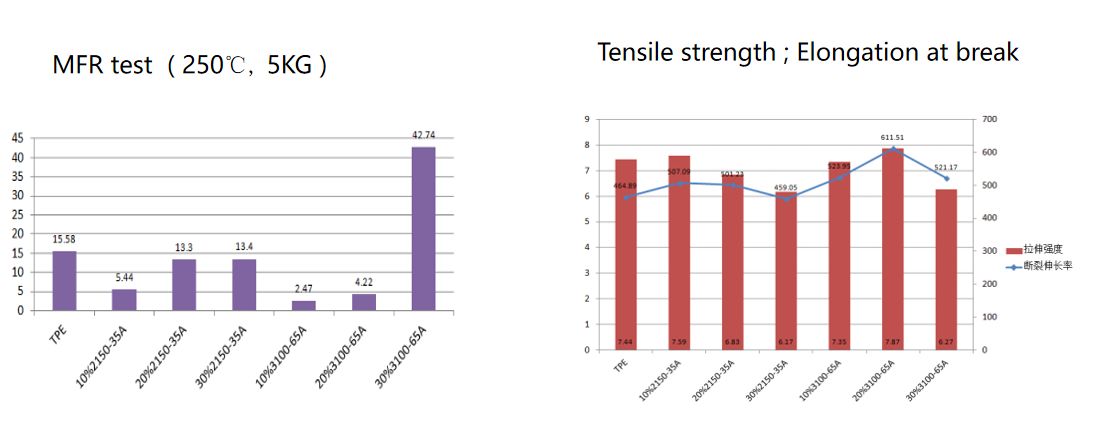

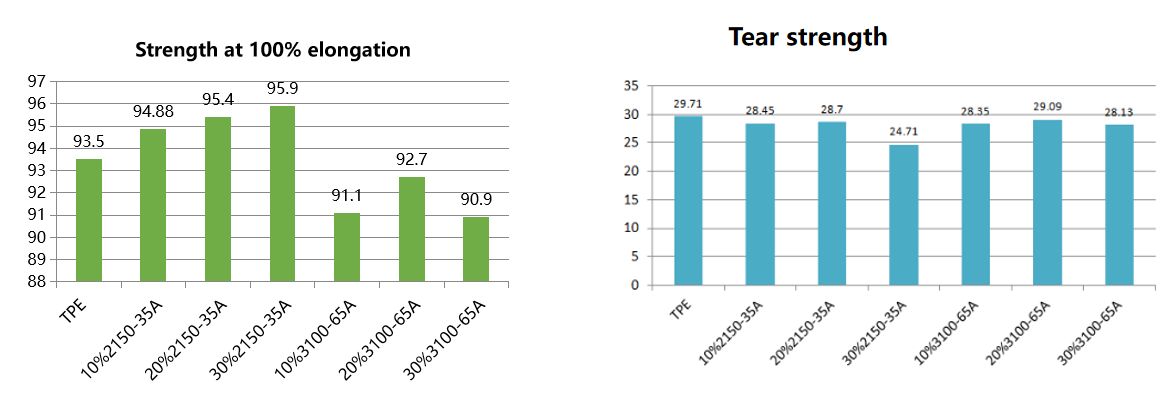

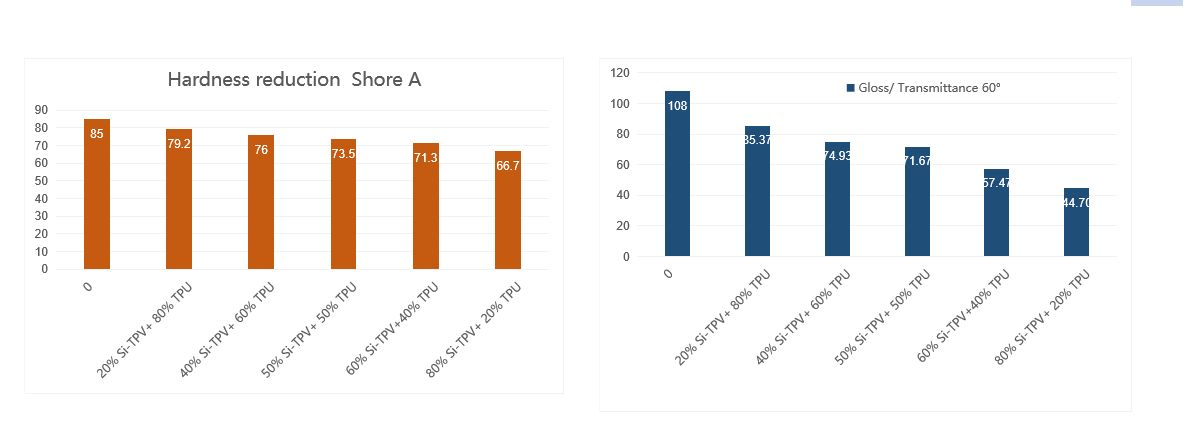

- Ka TPE

- 1. Khanyetso ea ho khohlela

- 2. Ho hanyetsa matheba ka sekhutlo se senyenyane sa ho kopana le metsi

- 3. Fokotsa ho thatafala

- 4. Ha ho na tšusumetso e kaalo hodima thepa ya mechini ka letoto la rona la Si-TPV 2150

- 5. Li-haptic tse ntle haholo, ho omella ha silika, ha ho thunya kamora tšebeliso ea nako e telele

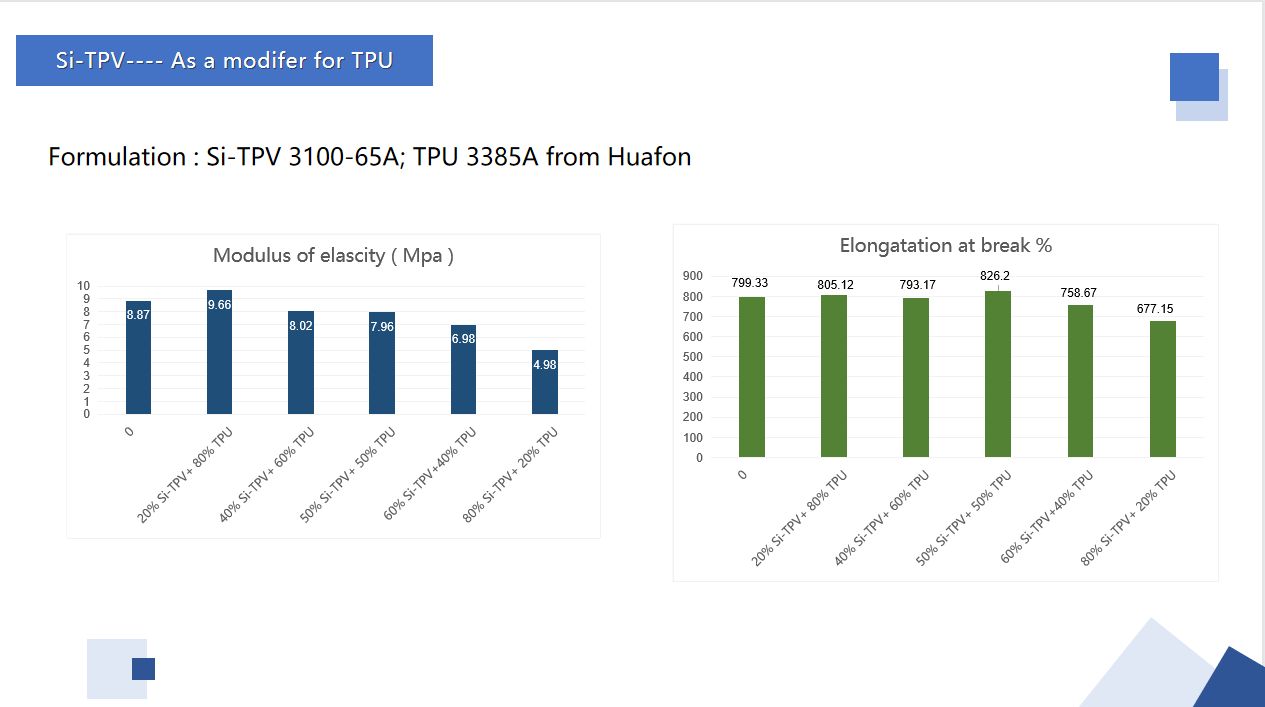

- Ka TPU

- 1. Phokotso ea ho thatafala

- 2. Li-haptic tse ntle haholo, ho omella ha silika, ha ho thunya kamora tšebeliso ea nako e telele

- 3. Fana ka sehlahisoa sa ho qetela sa TPU se nang le bokaholimo bo nang le phello e matte

- 4. Ho ama hanyane thepa ea Mechanical haeba ho eketsoa ho feta 20%

Ho tšoarella Botsitso

- Theknoloji e tsoetseng pele e se nang ditharollo, e se nang polasetiki, e se nang oli e nolofatsang, ebile e se na monko.

- Tšireletso ea tikoloho le ho sebelisoa hape.

- E fumaneha ka mekhoa e lumellanang le melaoana

Si-TPV joalo ka mofetoleli le Tataiso ea tlatsetso ea ts'ebetso

Letoto la Si-TPV 2150 le na le litšobotsi tsa ho ama letlalo ka bonolo nako e telele, ho hanyetsa matheba hantle, ho se be le plasticizer le softener e ekelitsoeng, 'me ha ho na pula kamora tšebeliso ea nako e telele, haholo-holo e sebelisoang hantle bakeng sa ho lokisa li-elastomer tsa thermoplastic tse monate tse ikutloang joaloka siling.

Kopo

Ha o kgetha Si-TPV bakeng sa ditshebediso tsa ho etsa overmolding, mofuta wa substrate o lokela ho nahanelwa. Hase di-Si-TPV tsohle tse tla hokahana le mefuta yohle ya di-substrate. Ntle le ho sebedisa di-overmold tsa Si-TPV hloohong ya sesebediswa sa ho silila, ke mohopolo o motle ho sebedisa di-overmold tsa Si-TPV mmeleng wa sesebediswa kapa dikonopong - kae kapa kae moo ho nang le ho kopana ha letlalo, di-overmold tsa Si-TPV track TPE di ka etsa phapang. Tshebediso e ikgethang e ka kenyeletsa di-massager tsa mahetla le molala, di-massager tsa botle ba sefahleho, di-massager tsa hlooho, jj.

Lisebelisoa tsa pele tsa ho silila tse seng tsa mechini ke tsa lehong, lihlahisoa tse ling tsa ho silila tsa mechini le tsona ke tsa lehong. 'Me joale e fetoloa haholo ho sebelisa thepa ea silicone e le thepa ea ho koahela sesebelisoa sa ho silila. Ha e bapisoa le hlooho ea ho silila ea lehong, silicone e bonolo ebile e hanela mocheso o phahameng, empa ho ama ha eona bokaholimo ho loketseng letlalo ho hloka ho lateloa ke kalafo ea ho silila, e bakang khatello tikolohong, 'me tšebeliso ea nako e telele e tla angoa ke ho koahela ho tloha ha e ama.

Kajeno, ka bongata bo ntseng bo eketseha ba thepa le nts'etsopele e tsoelang pele ea theknoloji ea thepa, khetho le tšebeliso ea thepa e ntse e e-ba ea bohlokoa haholo moralong oa sehlahisoa. U khetha thepa ea ho roala e fanang ka ho tenyetseha ho bonolo le maikutlo a tšoarellang nako e telele a bonolo letlalong le a boreleli?

Litharollo tse Bonolo: Ho Ntlafatsa Matšeliso ka ho Fetelletsa Lintho Tse Ncha >>