Lintlha tse qaqileng

Mathata a tikoloho a ntse a hlahella haholoanyane ha nts'etsopele ea moruo, 'me ho fihlela k'hemistri e tala ke mosebetsi o potlakileng matsatsing ana. Theknoloji ea foam e nang le tšusumetso e kholo ke theknoloji e ncha e nchafalitsoeng, lintho tse sebelisang foam tse sebelisoang theknolojing ea foam e nang le tšusumetso e kholo hangata ke carbon dioxide e nang le tšusumetso e kholo (ScCO2) le naetrojene e nang le tšusumetso e kholo (ScN2), tseo ka bobeli li sebelisoang ntle le moroalo oa tikoloho. Foam ea EVA (Ethylene Vinyl Acetate) ke thepa e tloaelehileng ea polasetiki e bobebe, e bonolo, le e tšoarellang e bileng ea bohlokoa indastering e fapaneng ka lebaka la ho tenyetseha ha eona, ho tenyetseha ha eona le ho sebelisa chelete hantle.

Melemo ea Bohlokoa

Ho tšoarella Botsitso

- Theknoloji e tsoetseng pele e se nang ditharollo, e se nang polasetiki, e se nang oli e nolofatsang, ebile e se na monko.

- Tšireletso ea tikoloho le ho sebelisoa hape.

- E fumaneha ka mekhoa e lumellanang le melaoana.

Tataiso ea ho ntša foam ea EVA

Letoto la Si-TPV 2250 le na le litšobotsi tsa ho ama letlalo ka bonolo nako e telele, ho hanyetsa matheba hantle, ho se be le polasetiki le senolofatsi se ekelitsoeng, 'me ha ho na pula kamora tšebeliso ea nako e telele, haholo-holo e sebelisoang hantle bakeng sa ho lokisa thepa ea foam ea EVA e nang le elastic e phahameng e sireletsang tikoloho.

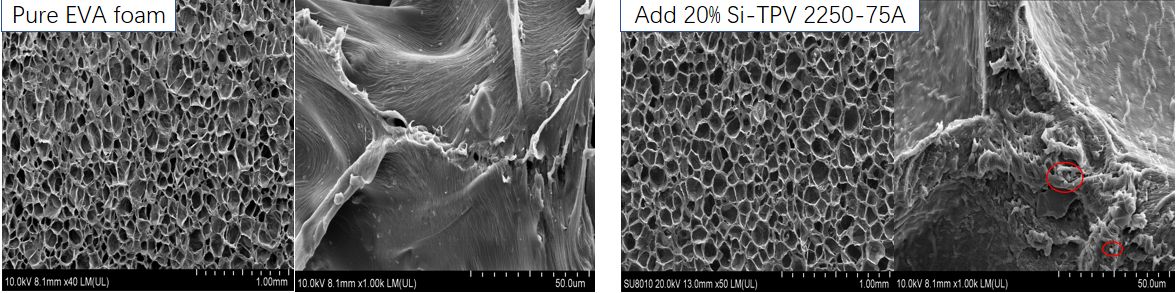

Kamora ho eketsa Si-TPV 2250-75A, bongata ba sele ea bubble ea foam ea EVA boa fokotseha hanyane, lebota la bubble lea teteana, 'me Si-TPV e hasana leboteng la bubble, lebota la bubble le ba thata.

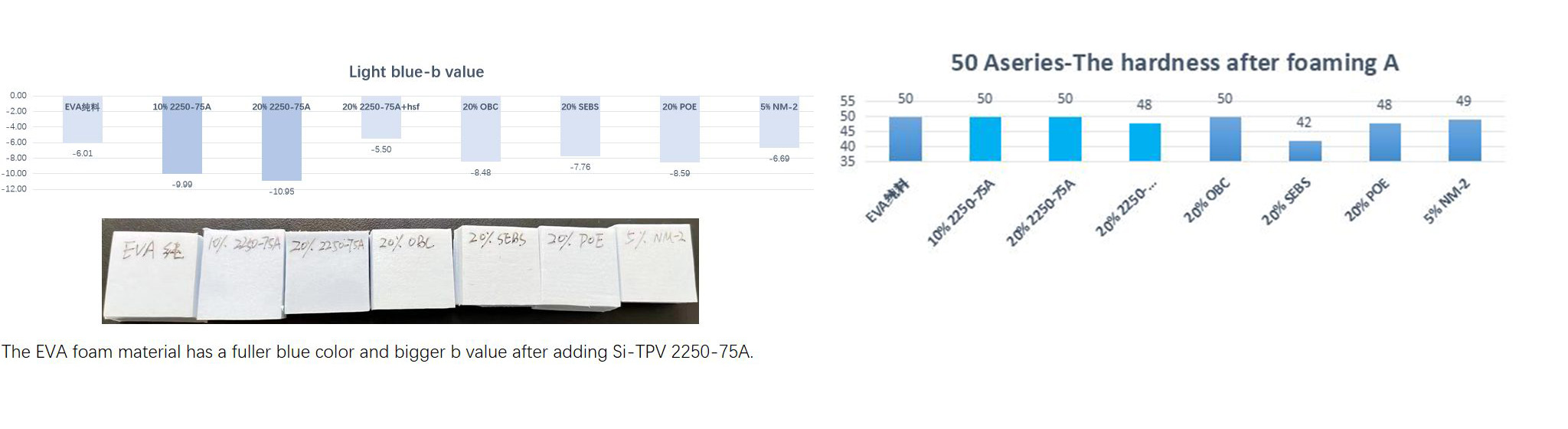

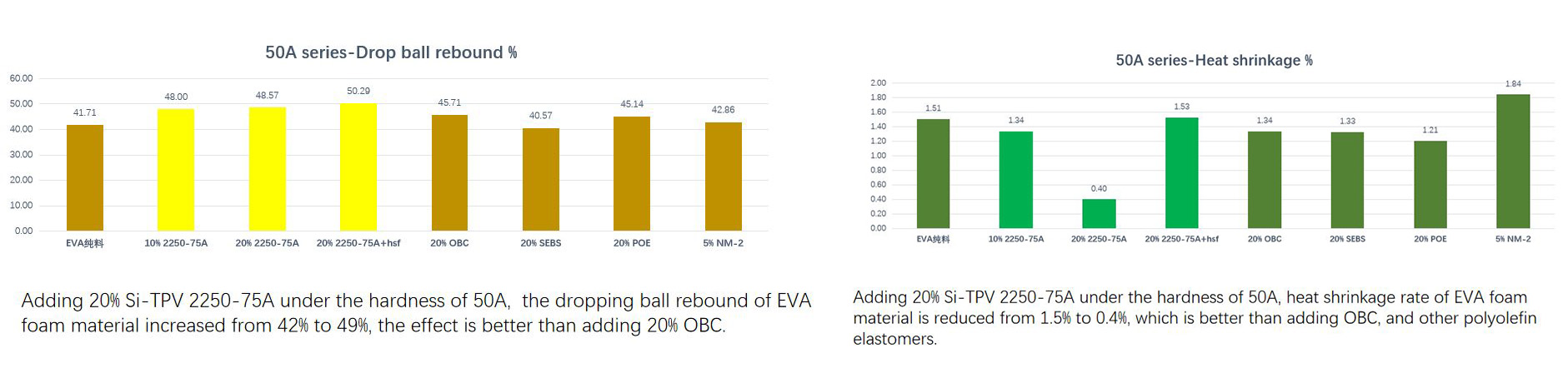

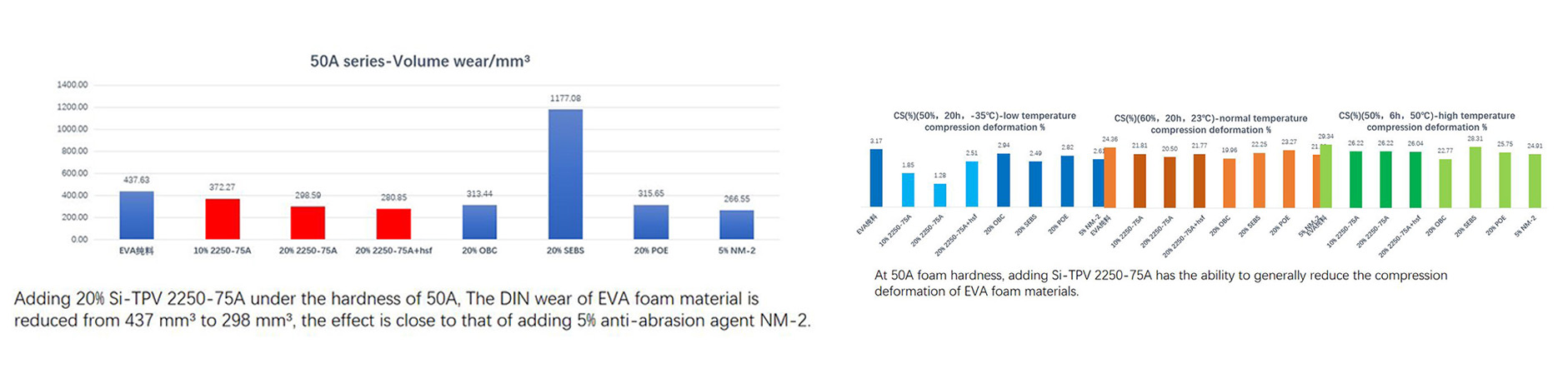

Papiso ea Si-TPV2250-75A le litlamorao tsa ho eketsa elastomer ea polyolefin foam ho foam ea EVA

Kopo

Sehlomathiso se secha sa Si-TPV se sireletsang tikoloho se matlafatsang thepa e ntšang foam ea EVA e ileng ea fetola bophelo ba letsatsi le letsatsi le liindasteri tsa lihlahisoa tsa mesebetsi ea khoebo. Tse kang lieta, lihlahisoa tsa bohloeki, lihlahisoa tsa boikhathollo ba lipapali, limmete tsa fatše/yoga, lintho tsa ho bapala, liphutheloana, lisebelisoa tsa bongaka, lisebelisoa tsa tšireletso, lihlahisoa tse sa thelleng tsa metsi, le liphanele tsa photovoltaic…

Mohlala, tlhahisong ea lihlahisoa tsa lieta, thepa e tloaelehileng ea foam bakeng sa li-sole, li-insole, le li-insole liners ke thepa ea EVA, e bapalang karolo ea ho tšehetsa le ho sireletsa maoto ka katleho le ho ntlafatsa boiketlo ba ho roala. Ho phaella moo, foam ea EVA e boetse e sebelisoa haholo indastering ea liphutheloana. Ka lebaka la bobebe ba eona 'me e na le thepa e ntle ea ho sireletsa le ho sireletsa, foam ea EVA hangata e sebelisoa ho etsa mabokose, li-cushion tsa liphutheloana, jj., ho sireletsa sehlahisoa ho tsoa tšenyo ea ho thothomela le ho tsoa ha lintho nakong ea lipalangoang. Ehlile, foam ea EVA e boetse e sebelisoa hangata tlhahisong ea lisebelisoa tsa lipapali. Mohlala, lisebelisoa tsa boikoetliso, li-yoga materase tse entsoeng ka thepa ea foam ea EVA li na le ts'ebetso e ntle ea ho thibela ho thella, ho se kene metsi le ho phutholoha, e fa barati ba yoga tikoloho e sireletsehileng le e phutholohileng ea boikoetliso. Ka kakaretso, foam ea EVA ke thepa e feto-fetohang haholo. Thepa ea eona e bobebe, e bonolo le e tšoarellang e etsa hore e be ts'ebeliso ea bohlokoa lihlahisoa tsa lieta, liphutheloana, lisebelisoa tsa lipapali le masimo a mang. Leha ho le joalo, tšusumetso ea tikoloho ea tlhahiso ea foam ea setso ea EVA e hlahisitse matšoenyeho, e leng se ileng sa etsa hore ho batloe mekhoa e meng e tsitsitseng.